Tekla is a vital tool for structural and civil engineers due to its capability to effortlessly manage engineering calculations and generate professional outcomes.

In today’s rapidly evolving construction industry, the mixing of advanced technology is reshaping traditional practices and driving unparalleled performance and precision. Among those transformative gear, Tekla software program sticks out as a sport-changer, revolutionizing construction approaches and turning in remarkable benefits to stakeholders across the globe.

Introduction to Tekla Software:

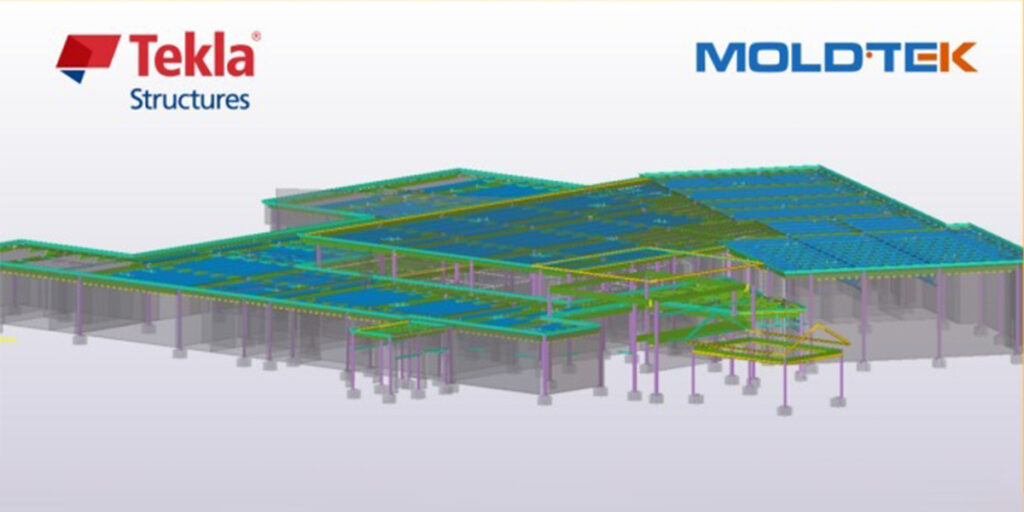

Tekla Structures is powerful building information modeling (BIM) software developed by Trimble Solutions Corporation. It is widely used in the construction industry for creating accurate and detailed models of buildings and structures. Tekla Structures is particularly renowned for its effectiveness in steel detailing, as well as in concrete detailing and other disciplines within the construction industry.

Architects, engineers, and construction professionals around the world trust Tekla Structures for its robust capabilities in creating comprehensive BIM models. With its user-friendly interface and advanced features, the software enables users to emciently design, analyze, and manage the entire construction process. From conceptualization to execution, Tekla Structures streamlines workflows and enhances collaboration among project stakeholders.

Here are some key aspects of Tekla Structures and its usage in steel detailing:

Modeling Capabilities: Tekla Structures allows users to create 3D models of steel structures with precision and emciency. Users can model various steel components such as beams, columns, braces, connections, and more. The software offers a comprehensive library of parametric components that can be easily customized to match project requirements.

Connection Design: Tekla Structures provides tools for designing and detailing steel connections. Users can define connection types, specify connection parameters, and generate detailed drawings and reports for fabrication and construction.

Fabrication Drawings: Tekla Structures generates detailed fabrication drawings automatically from the 3D model. These drawings include dimensions, annotations, and other information necessary for fabrication and erection of steel components.

Information Sharing: Tekla Structures supports interoperability with other software commonly used in the construction industry, such as Autodesk Revit and Navisworks. This facilitates collaboration and information sharing among project stakeholders.

Data-pushed Decision Making: Tekla’s complete BIM surroundings empowers project teams to make informed decisions based totally on actual-time data. By visualizing the complete mission lifecycle from thought to of entirety, stakeholders can discover ability issues early, optimize designs, and streamline construction workflows.

Clash Detection and Coordination: One of the strengths of Tekla Structures is its clash detection and coordination capabilities. Users can identify clashes between steel components and other building elements, helping to prevent conflicts and errors during construction. This proactive strategy reduces costly rework and delays, ensuring a more streamlined project implementation.

Prefabrication and Modular Construction: Tekla’s advanced modeling capabilities support prefabrication and modular construction techniques, enabling contractors to produce off-site building components more accurately and emciently. This off-site construction reduces on-site labor and enhances construction speeds up work, reduces costs and increases productivity.

BIM Collaboration: Tekla Structures enables seamless collaboration among architects, engineers, contractors, and fabricators through BIM. Changes made to the model are automatically updated and synchronized, ensuring that all project participants have access to the latest information. Integration with Production Control Systems: Tekla Structures can be integrated with production control systems used in steel fabrication shops. This integration streamlines the fabrication process by providing accurate and detailed information directly from the 3D model.

Overall, Tekla Structures is a versatile and powerful software solution for steel detailing, offering advanced modeling, coordination, and collaboration capabilities that help streamline the design, fabrication, and construction processes in the steel industry.

Case Studies and Real World Impact:

Several case studies and real-life instances showcase the significant influence of Tekla software on the construction sector worldwide. Whether it’s iconic skyscrapers, intricate infrastructure, cutting-edge technologies, or sustainable structures, Tekla’s role in the construction industry is unquestionable.

Example 1: The Burj Khalifa

The Burj Khalifa in Dubai, the world’s tallest building, was created using Tekla software for its intricate design and geometry. Tekla Structures played a crucial role in accurately modeling the complex structure, enabling a seamless workflow and successful completion of this iconic landmark.

Example 2: The Tekla Software has played a crucial role in the development of high-speed rail projects globally. With its advanced Building Information Modeling (BIM) features, it enables seamless coordination among various disciplines such as architecture, engineering, electrical, and architectural design. This leads to enhanced emciency in construction tasks and accelerated project completion times.

Moldtek Technologies’ Project Excellence with Tekla

Moldtek Technologies showcases exemplary project excellence with Tekla, enhancing construction processes with accuracy and efficiency. Whether it’s optimizing commercial buildings or overseeing intricate infrastructure projects, their proficiency guarantees timely delivery and superior results, underscoring their position as industry leaders.

Example 1: Sentara Albemarle Medical Center

Location: Elizabeth City, NC

Type: Health Care

Tonnage: 960

This hospital building project comprises four floors and a roof structure. The main steel components include stairs and steel-to-concrete connections. Coordination efforts are focused on canopies at the entry level, embed plates, and deck drawings. Special attention is given to screen wall framing steel coordination, along with concrete-to-steel connections, stairs, elevators, canopy structures at the entry, and cross-checking rebar details. The project involves a dedicated team of 5 to 7 members working continuously to meet the tight schedules

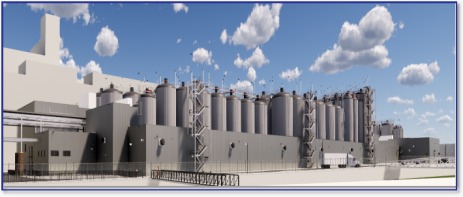

Example 2: MOLSON Coors

Location: Golden, Colorado

Type: Manufacturing

Tonnage: 3025

Molson Coors is a beverage company having few building in the name of process areas with interior and exterior pipe-racks, stair towers along the side of the building perimeter to get access to top of beverage tanks. This project will replace fermenting, aging, filtering and storage facilities at company’s giant Golden brewery.

it is the second-largest beer-making facility in the world. Embeds were all over the job as the core structure columns/slabs was designed with concrete. Embed coordination with the steel is major part. There were total 55 sequences to detail in this project.

Conclusion:

Tekla Software is transforming the construction sector by providing stakeholders with cutting-edge BIM capabilities. This enhances collaboration, accuracy, and emciency throughout the project’s duration. As the construction industry evolves and requires more innovation through Tekla’s advancements, the performance and achievements in the built environment are expected to rise significantly. With Tekla’s solutions leading the path, the industry is prepared to tackle challenges with resilience and creativity, ensuring sustainable progress and growth in evolving environments.